STRUCTURAL TESTING (AC86 NON LOAD-BEARING, AC46 LOAD-BEARING)

The R-stud’s design allows builders to deliver higher walls with less material and less deflection. The supplemental flanges every foot increase the strength. A 20-gauge R-stud, 24” O.C. has a limiting wall height of 19.64 vs. a 20-gauge SSMA, 16” O.C. which only has an 18.11’ wall height limit. R-stud delivers higher limiting wall height with fewer or lighter studs.

STRENGTH

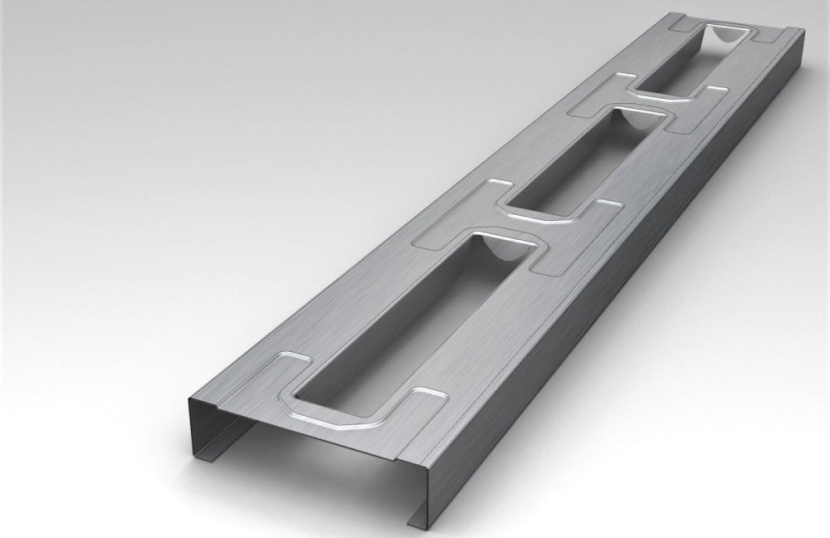

Stronger Geometry than a standard stud

Stronger geometry means less steel needed to attain the same structural strength as a conventional steel stud, thus less raw material is required to manufacture the steel stud.

Supplemental Flanges & Embossing

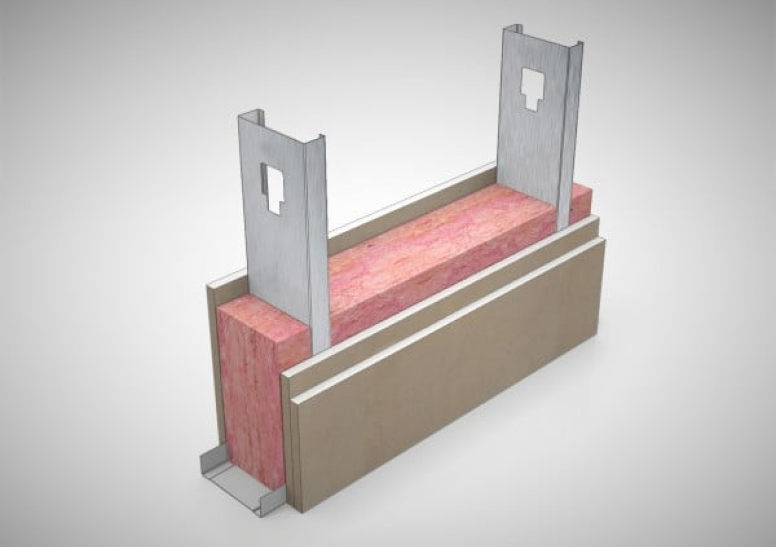

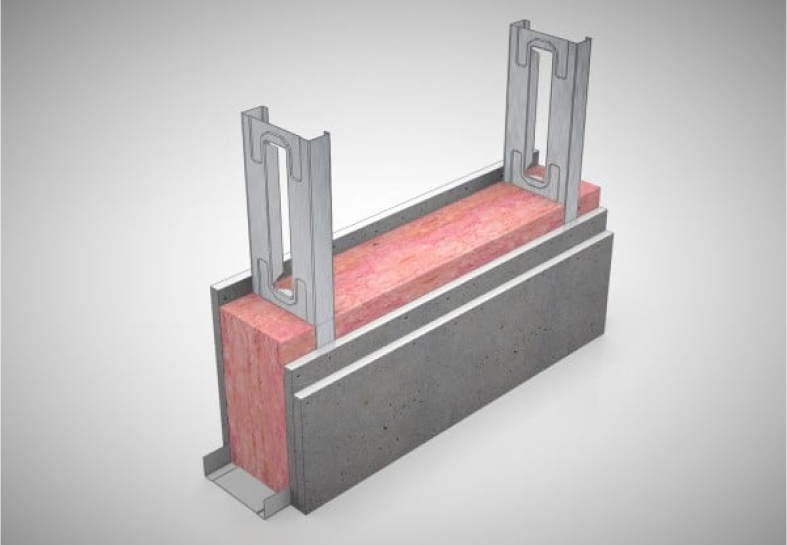

Increased strength of stud allows for increased spacing of studs.

Increasing from 16” to 24” spacing equals 1/3 LESS studs needed

Cross bracing with only an L or C channel and a screw – no need for special connectors = less time and expense.

R-stud becomes more competitive as steel costs increase.

Stronger Geometry than a standard stud

R-stud can reduce steel thickness with greater strength and/or 24-inch on center spacing vs 16 inch = less Embodied Carbon

FINITE ELEMENT ANALYSIS-

With the same loading applied; 200 lbs. vertically down load, and 55 mph side wind force [Pounds per square foot = 0.0026 (55)2 = 8 lbs./ft2 of wall] over a 2-ft strip 10-ft long the following results were obtained:

Conventional Stud - STC 44

18-gauge (0.0451 inch thick material SSMA) generic steel Stud is computed to have: MAXIMUM QUAD ELEMENT PRINCIPAL STRESS = 15.11 ksi at element 1042 (Tensile).

R- Stud

20-gauge (0.0346 inch thick material SSMA) structural Rstud® is computed to have: MAXIMUM QUAD ELEMENT PRINCIPAL STRESS = 15.27 ksi at element 1205 (Tensile).

CONCLUSIONS

-

.png)

A 20-gauge R-stud, 24” O.C. has a limiting wall height of 19.64 vs. a 20-gauge SSMA, 16” O.C. which only has an 18.11’ wall height limit. R-stud delivers higher limiting wall height with fewer studs.

-

.png)

The 15.27 ksi stress value for the 20-gauge Rstud® reveals it to be superior to the 18-gauge generic stud with a 15.11 ksi stress value.

-

.png)

The 15.27 ksi modeling value is based on conservative modeling assumptions. The production Original Rstud® with high-speed cold working should exhibit greater strength and could potentially allow for a 3-gauge substitution spread allowing for a lighter weight, low cost, simple design.